A standby generator should be maintained at home to ensure it remains dependable during power outages. Professional service, weekly checks, fuel and battery, seasonal fluid and filter checks, and annual checks are guaranteed to keep the operation running smoothly. Maintaining your generator will help prevent failures, extend its life, secure your warranty, and ensure it provides backup power when it is most needed in your home.

The significance of Generator Maintenance.

A home standby generator is a significant sum of money, which you spend on the comfort and security of your family. When the power goes off, you use it to turn on the lights, refrigerator, and lock up your house. Nevertheless, like any complex machine, a standby generator cannot be efficient without regular maintenance. You can spare it and be about to fail at the most important moment.

Some of the common problems are: a dead battery, a blocked fuel line, a broken transfer switch, or a broken engine that might not enable your Generator to start. Routine maintenance will assist in detecting such problems in time to save your investment and ensure that the next time there is a power outage, your Generator will be available.

This checklist will help you know what to check, how often to check it, and what the best practices are to keep your standby system going so that it is available when you need it.

Weekly/Monthly Quick Checks

These are the simplest types of inspections that most homeowners can perform, and this is the first line of defense against the common generator problems.

Running test and visual inspection test.

Firstly, make a tour of the unit. Look in the house, in the basement, or in any other corner, to determine whether there is any rubble, standing water, or signs of insects or pests. Make sure that the air vents are open, as they are necessary in making sure that cooling is carried out.

Make sure the Generator is set to auto mode. Such an environment will cause it to turn on in case of a power outage automatically. Most of the modern standby generators have an automatic exercise cycle, i.e., they are switched on to run about 20-30 minutes once a week to ensure that the engine is lubricated and running. Test this by listening to it run and making sure that it is smooth. You will run your unit manually and for the same time period in case your unit does not have an auto-exercise option.

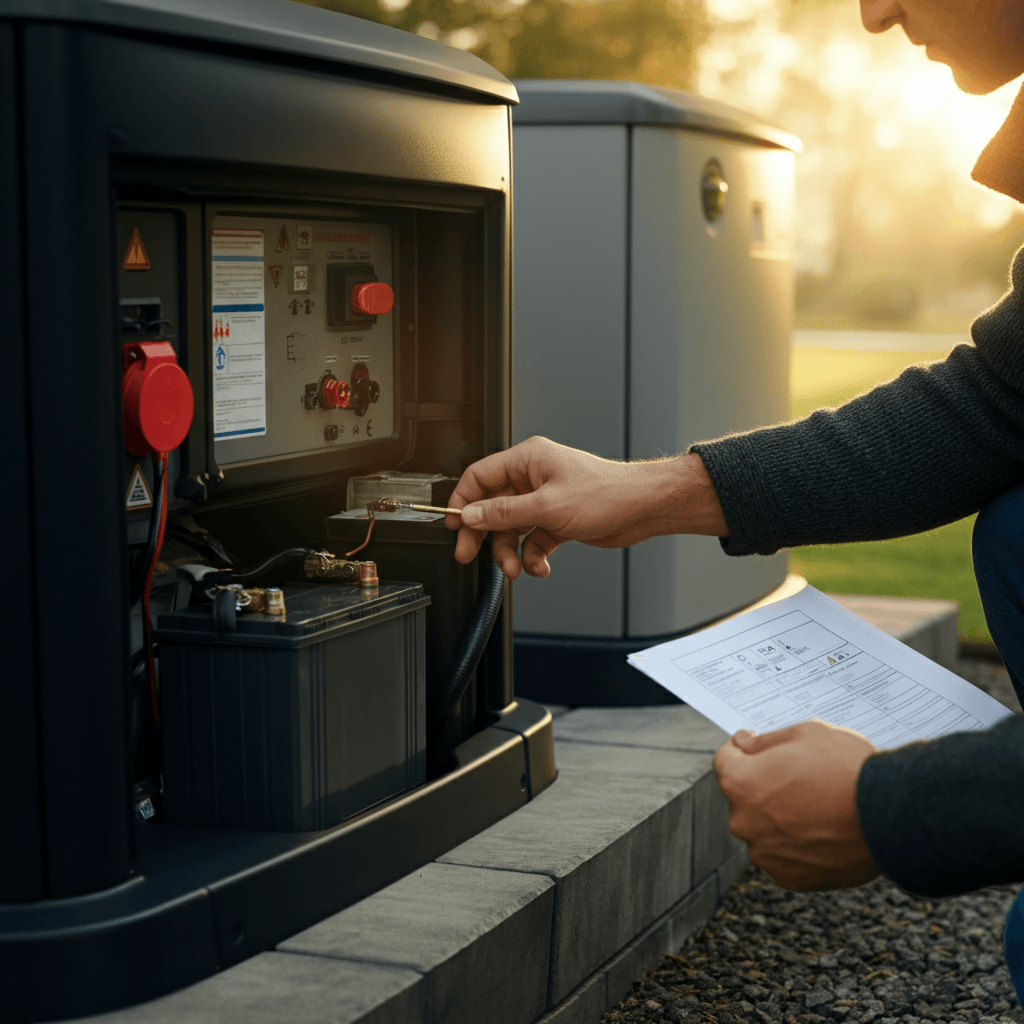

Fuel & battery check

The battery is one of the most prevalent places of failure. Check the battery posts physically to know whether they are corroded or not; corrosion is a white or greenish powdery substance. Ensure the battery charger is properly plugged in and working; most commonly, they have a light indicator.

Next, check your fuel supply. Test your propane tank to ensure that you have propane as your Generator. To ensure it is not connected to a natural gas line, ensure that the valve is open and there is no leakage.

Clear the area

Remember also to make sure the surroundings of the generator enclosure are clear so that there is proper ventilation. Regularly clean up the accumulated leaves, snow, ice, or any other debris. This is especially required after the storms or high foliage, or snow cover seasons.

Maintenance is done quarterly or seasonally.

These are stricter inspections that should be done every three months to ensure that your home generator is in the best condition.

Check fluids & filters.

Test the engine oil level as you would with a car. Moreover, check the amount of engine coolant as well in case your Generator is liquid-cooled. Inspect the air filter, the fuel filter. They may need to be replaced in case they are clogged or dirty. Even though some of the homeowners feel comfortable changing these, the majority of them leave it to their annual professional service.

Check belts, exhaust system, and hose.

Determine whether there is any visible wear and tear. Check the engine belts and make sure that they are not torn or ripped. Check hoses to determine whether there are leaks, soft, or deteriorated. Check the exhaust system to determine whether it is rusted, has holes, or loose fittings, which can be dangerous to safety.

Checking of the transfer switch / electrical system.

The automatic transfer switch (ATS) is the part that is needed to instruct your Generator to come on in case of a power outage. Make sure it works by testing it. During the time the Generator is on test. It is also possible to notice potential issues due to a rapid visual inspection of the wiring and connections in case of looseness or corrosion. Any detailed inspection of the electrical system should be carried out by a professional for safety reasons.

Professional Service and Load Test, Annual.

A full service to your standby generator must be performed on an annual basis by a certified technician.

Full analysis by a skilled technician.

A professional service is normally done once a year and normally includes the replacement of the oil and filter and replacement of the spark plugs, and a comprehensive inspection of the alternator and other internal components. This service can also have a coolant flush or battery replacement based on the age of the unit and the number of hours used. Technicians have the diagnostic tools to identify the problems that lie behind the scenes that cannot be seen with the naked eye.

Load testing under real-life conditions.

A load bank test is a significant part of annual maintenance. The technician will check the Generator and make sure that it is capable of providing power to all the circuits you want to install in your home in the event of a power failure at a realistic load. It is a test that is necessary to make sure that your Generator is not just starting, but can meet the demands of your home during the required appliances and systems during a long power outage.

Bookkeeping and warranty.

Keep a detailed account of all the tests, maintenance, and repairs performed on your Generator. Many manufacturers require the warranty to be retained by having a documented annual service done by an authorized technician. These records also assist in troubleshooting any future issues, and also in proving the good care in the event that you decide to sell your house.

Best Practices of safe and reliable operations.

- Always leave the unit in the Auto mode so that it will automatically start when the utility power goes off.

- Pre-emption of the schedule before extreme weather. Just in case your location is a hurricane, blizzard, or any other extreme weather location, you should have your Generator serviced before the season begins.

- The battery should be changed after 2-3 years or as per the manufacturer. Battery malfunction is one of the reasons that leads to the start of generators.

- Ensure that the area of the unit is well clear and ventilated.

- Only qualified parts and service technicians are to be employed. This will help to avoid the nullification of the warranty, and one of the methods of ensuring that the repairs are well executed.

- Know your fuel supply. When using propane, ensure that the tank is well filled. With natural gas, you have to be informed as to the reliability of your local supplier in case of a large-scale outage.